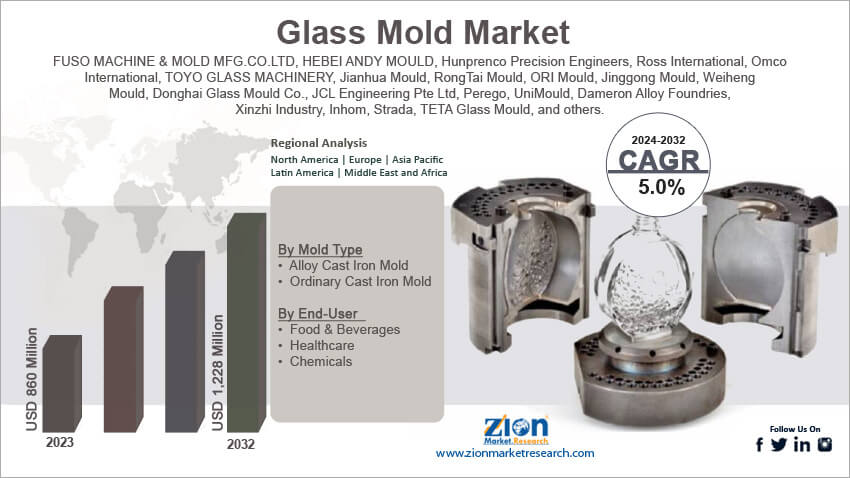

The Glass Mold Market plays a critical role in the global glass manufacturing ecosystem, supporting the production of glass containers, tableware, lighting components, pharmaceutical packaging, and specialty glass products. Glass molds are precision-engineered tools used to shape molten glass into standardized or customized forms, ensuring consistency, durability, and aesthetic quality. As demand for glass products continues to rise across industries such as food & beverage, pharmaceuticals, cosmetics, and construction, the glass mold market is witnessing steady growth worldwide.

Market Overview

Glass molds are typically manufactured using high-grade materials such as cast iron, alloy steel, and bronze to withstand extreme temperatures and repetitive production cycles. These molds are essential in glass container manufacturing processes including blow-and-blow, press-and-blow, and narrow neck press-and-blow (NNPB) techniques. The market is characterized by a strong focus on precision engineering, thermal resistance, and extended mold life.

The growing preference for glass over plastic—driven by sustainability concerns and regulatory pressures—is a key factor fueling the demand for glass molds. Glass is recyclable, chemically inert, and suitable for premium packaging, making it a preferred choice for manufacturers and consumers alike.

Key Market Drivers

One of the primary drivers of the glass mold market is the expanding food and beverage industry, particularly in bottled water, alcoholic beverages, and soft drinks. Glass packaging is widely used due to its ability to preserve product quality and flavor without contamination.

The pharmaceutical and healthcare sectors also contribute significantly to market growth. Glass containers such as vials, ampoules, and bottles require highly precise molds to meet strict quality and safety standards. Rising global healthcare expenditure and increased pharmaceutical production are boosting demand for advanced glass molding solutions.

Additionally, the cosmetics and personal care industry is driving innovation in glass mold design. Premium glass packaging with unique shapes and branding elements requires customized molds, increasing demand for high-precision and decorative mold solutions.

Market Segmentation

The glass mold market can be segmented based on material type, mold type, application, and end-user industry.

By material type, cast iron molds dominate the market due to their durability and cost-effectiveness. However, alloy steel and bronze molds are gaining popularity for high-performance and specialty applications where longer mold life and improved surface finish are required.

Based on mold type, the market includes blank molds, blow molds, neck ring molds, and plunger molds. Blank and blow molds hold a significant share, as they are essential components in container glass production lines.

In terms of application, container glass manufacturing represents the largest segment, followed by tableware, lighting glass, and technical glass. The container glass segment benefits from consistent demand across food, beverage, and pharmaceutical industries.

Regional Analysis

Regionally, the glass mold market is well-established in Europe and North America, supported by advanced manufacturing infrastructure and strong demand for premium glass packaging. These regions emphasize innovation, automation, and mold longevity to enhance production efficiency.

The Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization, urbanization, and expanding consumer markets in countries such as China, India, and Southeast Asian nations. The increasing presence of glass container manufacturers and growing exports of glass products are creating strong opportunities for mold suppliers in this region.

Meanwhile, Latin America and the Middle East & Africa are emerging markets, supported by growth in food processing, beverage production, and pharmaceutical manufacturing.

Technological Advancements

Technological innovation is a major trend shaping the glass mold market. Manufacturers are increasingly adopting computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies to improve mold accuracy and reduce lead times. Advanced surface coatings and treatments are also being developed to enhance mold life, reduce glass sticking, and improve heat resistance.

Automation and smart manufacturing practices, including predictive maintenance and digital monitoring, are gaining traction. These technologies help reduce downtime, improve production consistency, and lower overall operational costs for glass manufacturers.

Competitive Landscape

The glass mold market is moderately fragmented, with a mix of global and regional players competing on quality, customization, and technical expertise. Leading manufacturers focus on long-term partnerships with glass producers, offering tailored solutions and after-sales services such as mold refurbishment and maintenance.

Competition is driven by factors such as mold lifespan, precision, delivery time, and cost efficiency. Companies are also investing in research and development to create innovative mold designs that support lightweight glass containers and complex shapes.

Challenges and Restraints

Despite positive growth prospects, the glass mold market faces several challenges. High initial investment costs for precision molds and advanced manufacturing equipment can be a barrier, particularly for small and medium-sized enterprises. Additionally, fluctuations in raw material prices can impact production costs and profit margins.

The market also faces competition from alternative packaging materials such as plastics and metals in certain applications. However, increasing environmental awareness and regulatory support for sustainable packaging are helping glass regain market share.

Future Outlook

The future of the glass mold market appears promising, supported by rising demand for sustainable packaging, premium glass products, and pharmaceutical containers. Continued innovation in mold materials, coatings, and digital manufacturing techniques is expected to enhance efficiency and product quality.

As glass manufacturers focus on lightweighting, customization, and energy-efficient production, the demand for advanced and high-performance glass molds will continue to grow. Emerging economies, in particular, are expected to provide lucrative growth opportunities over the forecast period.

Conclusion

In conclusion, the Glass Mold Market is a vital component of the global glass manufacturing industry, enabling high-quality, efficient, and sustainable glass production. Driven by strong demand from food & beverage, pharmaceutical, and cosmetic industries, along with technological advancements and sustainability trends, the market is set for steady expansion. Companies that invest in innovation, customization, and long-term customer relationships are likely to gain a competitive edge in this evolving market landscape.

Other Report Zion Market Research:

https://www.zionmarketresearch.com/de/report/home-furnishings-market

https://www.zionmarketresearch.com/de/report/industry-5-0-market

https://www.zionmarketresearch.com/de/report/india-construction-equipment-market

https://www.zionmarketresearch.com/de/report/wheatgrass-products-market

https://www.zionmarketresearch.com/de/report/animal-artificial-insemination-market